Sheet Moulding Compound(SMC) Material Turkey

Huayuan Advanced Materials Co., Ltd. (HAMC) is a professional and active leader focusing on formulating, compounding, and molding of thermosetting composites materials and products. HAMC has been working with industry equipment, electrical, telecom, automotive, train, fast transit, home appliance and construction for over 26 years globally. With continuous R&D development, HAMC has gained long term & global partnership with Siemens, GE, Schneider, Eaton, Cummins, and over 20 cities fast transit projects in China.

What is Sheet Moulding Compound (SMC)?

Sheet molding compound (SMC) is a chopped glass fiber (usually 1 inch) based on unsaturated polyester (or vinyl) resin or other fiber-reinforced composite materials similar to natural fibers. A stable, moldable composite material, which has viscosity and excellent moldability on the sheet, and is used to produce various complex components. SMC is used in the construction and automotive fields. There are building materials, bathroom materials, and building water tanks, as well as battery boxes, car parts, trunk doors and car tailgates. Especially with the commercialization and sales increase of new energy vehicles (pure electric vehicles, hybrid vehicles), the SMC material market is expected to further expand.

Sheet molding compound (SMC) has light weight, high mechanical strength, electrical insulation, fire resistance, corrosion resistance, heat resistance, weather resistance, low shrinkage, stable dimensional control, uniform material thickness, and combines a variety of special properties to make SMC Become the most ideal manufacturing material for heavy-duty truck/automobile body parts (A-level surface), indoor/outdoor cabinets for different equipment, molded door skins, various complex structural components in electrical or other industries.

HAMC Provides a Complete Sheet Moulding Compound Solution

HAMC has long provided SMC materials for various industries, including electrical insulation, fireproof, corrosion or heat-resistant parts, agriculture, automobiles, construction, electricity, energy, HVAC, lighting, military, rapid transportation, security, solar/wind energy, telecommunications, etc. . More than 26 years of manufacturing and R&D experience can ensure to provide you with comprehensive technical support. From sheet molding compound (SMC), bulk molding compound (BMC) material formulation, product design support, mold design and manufacturing, and final molded products, HAMC can always find better choices for customers to achieve better performance and Cost-effectiveness. If you want to obtain products with the above characteristics or reduce costs, please contact us for detailed information, we believe you will find a suitable solution for you.

Fiber/Cable Distribution Cabinets

HUAYUAN (HAMC)’s fiber/cable distribution cabinets are made from sheet molding compound (SMC) material which is a polyester material reinforced with fiberglass. The frame is attributed with excellent performance of anti-erosion and anti-aging.

Fiber/Cable Distribution Cabinets

HUAYUAN (HAMC)’s fiber/cable distribution cabinets are made from sheet molding compound (SMC) material which is a polyester material reinforced with fiberglass. The frame is attributed with excellent performance of anti-erosion and anti-aging.

SMC Cable Trays

SMC (Sheet Molding Compound) material molded cable trays can serve over 30 years outdoor with NO maintenance. This is a revolutionary solution in cable tray industry.

SMC Cable Trays

SMC (Sheet Molding Compound) material molded cable trays can serve over 30 years outdoor with NO maintenance. This is a revolutionary solution in cable tray industry.

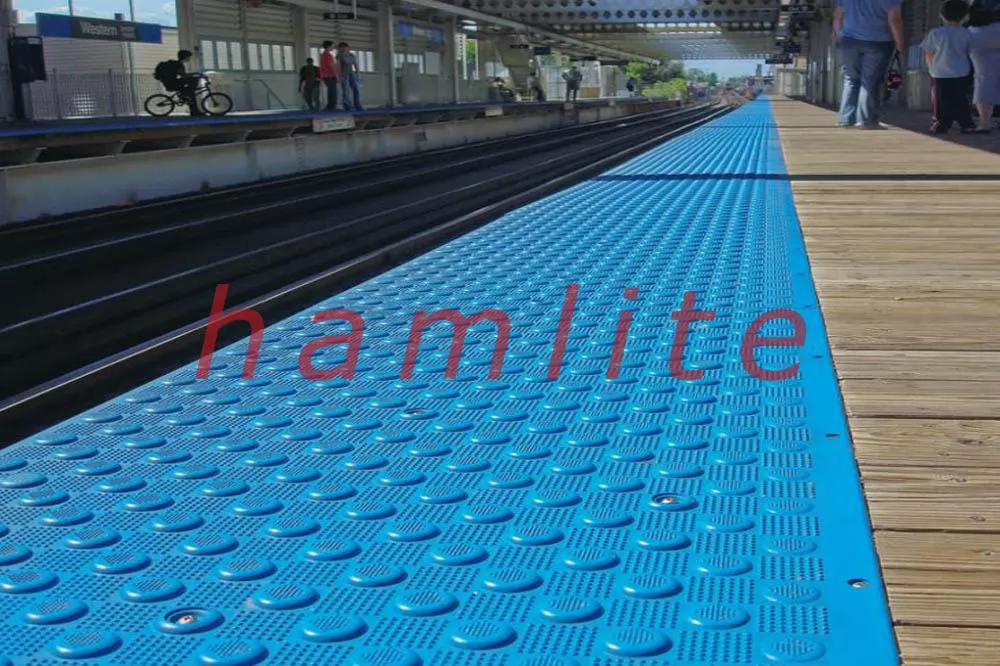

SMC Tactile Tiles

SMC (Sheet Molding Compound) material is a perfect material for tactile tiles due to its high strength, long serving life, maintenance-free and anti-wearing, etc.

SMC Tactile Tiles

SMC (Sheet Molding Compound) material is a perfect material for tactile tiles due to its high strength, long serving life, maintenance-free and anti-wearing, etc.

BMC Molded Motor Covers

Motor cover is a typical application of bulk molding compound (BMC) material. It replaced die cast aluminum/zinc parts by offering various advantages.

BMC Molded Motor Covers

Motor cover is a typical application of bulk molding compound (BMC) material. It replaced die cast aluminum/zinc parts by offering various advantages.

SMC Cable Brackets

Sheet Molding Compound (SMC) molded cable brackets that provided by Huayuan (HAMC) are used in many fields like power stations, subways, bullet train tracks.

SMC Cable Brackets

Sheet Molding Compound (SMC) molded cable brackets that provided by Huayuan (HAMC) are used in many fields like power stations, subways, bullet train tracks.

Anti-explosive Enclosures

Sheet molding compound (SMC) material, rigid, sustainable, low weight, fire resistant, chemical resistant, and long serving life, is a very suitable material for producing anti-explosive enclosures after adding special mineral agent into SMC material. Explosive working places are always protecting electrical equipments from leaking flashes. Working places are usually in very bad condition. This requires the protecting enclosures being very strong, and most importantly, self anti-explosive.

Anti-explosive Enclosures

Sheet molding compound (SMC) material, rigid, sustainable, low weight, fire resistant, chemical resistant, and long serving life, is a very suitable material for producing anti-explosive enclosures after adding special mineral agent into SMC material. Explosive working places are always protecting electrical equipments from leaking flashes. Working places are usually in very bad condition. This requires the protecting enclosures being very strong, and most importantly, self anti-explosive.

The reason why our SMC is popular in Turkey

Quality Assurance: The quality of our products meets various Turkeyn tests and certifications. After 26 years of hard work, HAMC has now become a leader in the Chinese industry. The SMC formulated and compounded by HAMC has been widely used in various industrial applications in China and around the world, and has been well received by customers all over the world.

There are distributors in Turkey: our customers are all over the world. We plan to produce overseas to provide faster and better service.

HAMC has established an advanced factory of more than 70,000 square meters in China. The R&D center has an area of more than 4,000 square meters.

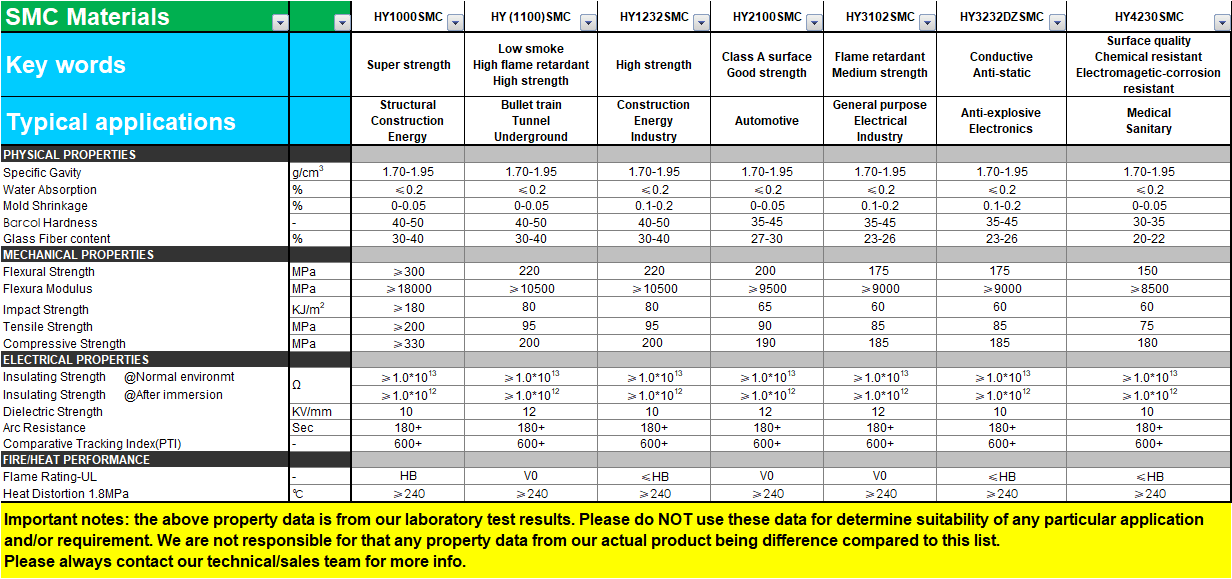

Provide different SMC specifications:

5 reasons tell you why you choose a sheet moulding compound manufacturer in China.

If you are currently looking for a competitive price and high-quality SMC material manufacturing partner, please contact HAMC for a quote.