SMC Sheet Molding Compound Factory

As SMC Sheet Molding Compound Factory, Huayuan Advanced Materials is a professional and active leader focusing on the formulation, compounding and molding of thermoset composite materials and products, and has been at the forefront of composite products for 26 years. HAMC has 70,000 square meters of factory buildings and plans to manufacture overseas to provide faster and better services. We have an experienced team of raw material analysis and development, structural design, mold engineering, quality management, control and inspection engineering. HAMC's technical consultant team can provide technical consultation, support and comprehensive solutions according to the individual needs of customers. Today, HMC is a leader in the design and marketing of composite solutions. Our products are exported to most countries in Europe and America, and have won a global reputation with high quality and excellent after-sales service. Hope and believe that HMC can become your trusted partner and create a win-win situation.

HAMC is the best SMC Sheet Molding Compound Factory

As SMC Sheet Molding Compound Factory, HAMC provides cost-effective and high-performance products, as well as the solutions and services provided. If you want to obtain products with the above characteristics or reduce costs, you can usually use SMC or BMC instead of metals, thermoplastics, phenolic resins or epoxy resins. The SMC and BMC produced by HAMC are used to manufacture electrical insulating parts, motor brackets, automobile headlight housings, and various structural and protective parts in different industries. HAMC has more than 26 years of experience in designing ideal and cost-effective SMC materials and BMC materials for customers in various industries and applications. Please contact us for detailed information, we believe you will find a suitable solution for you.

Reasons for choose SMC Sheet Molding Compound Factory

Quality Assurance

The quality of our products meets our various tests and certifications. After 26 years of hard work, HAMC has now become a leader in the Chinese industry. HAMC compounded SMC and BMC materials are now widely used in various industry applications in China and even the world.

There are distributors everywhere

our customers are all over the world. We plan to produce overseas to provide faster and better service.

Advanced R&D base

HAMC has established an advanced factory of more than 70,000 square meters in China. The area of the R&D center also exceeds 4000 square meters.

SMC Cable Brackets

Sheet Molding Compound (SMC) molded cable brackets that provided by Huayuan (HAMC) are used in many fields like power stations, subways, bullet train tracks.

SMC Cable Brackets

Sheet Molding Compound (SMC) molded cable brackets that provided by Huayuan (HAMC) are used in many fields like power stations, subways, bullet train tracks.

SMC Cable Trays

But these traditional materials are not staying long in outdoor applications like subway, train, or power stations because of chemical corrosion, UV, acid rain, or dusty wind. Some metal trays can even be stolen and destroyed. Serving lives of these traditional materials are within 10 years maximally. SMC (sheet molding compound) material perfectly solved these issues.

SMC Cable Trays

But these traditional materials are not staying long in outdoor applications like subway, train, or power stations because of chemical corrosion, UV, acid rain, or dusty wind. Some metal trays can even be stolen and destroyed. Serving lives of these traditional materials are within 10 years maximally. SMC (sheet molding compound) material perfectly solved these issues.

Electrical Meter Boxes

Electric meters, gas meters and water meters all require suitable, sustainable, rigid, light weight and cheap boxes to protect the inner meters and facilities. Sheet molding compound (SMC) material can meet all these typical requirements.

Electrical Meter Boxes

Electric meters, gas meters and water meters all require suitable, sustainable, rigid, light weight and cheap boxes to protect the inner meters and facilities. Sheet molding compound (SMC) material can meet all these typical requirements.

Fiber/Cable Distribution Cabinets

HUAYUAN (HAMC)’s fiber/cable distribution cabinets are made from sheet molding compound (SMC) material which is a polyester material reinforced with fiberglass. The frame is attributed with excellent performance of anti-erosion and anti-aging.

Fiber/Cable Distribution Cabinets

HUAYUAN (HAMC)’s fiber/cable distribution cabinets are made from sheet molding compound (SMC) material which is a polyester material reinforced with fiberglass. The frame is attributed with excellent performance of anti-erosion and anti-aging.

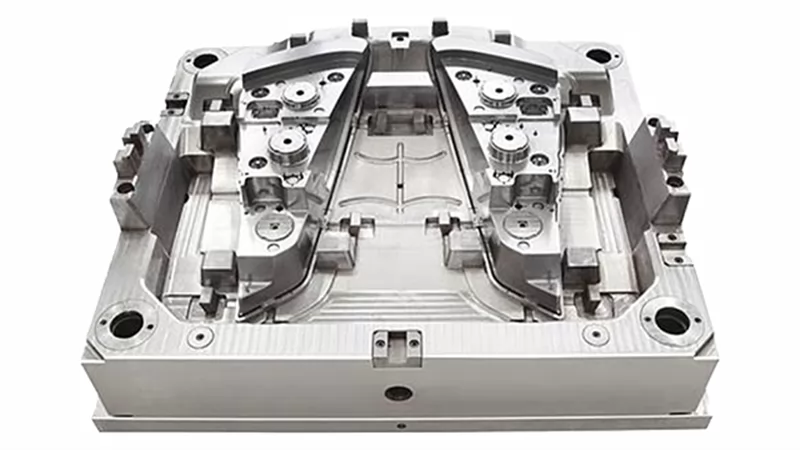

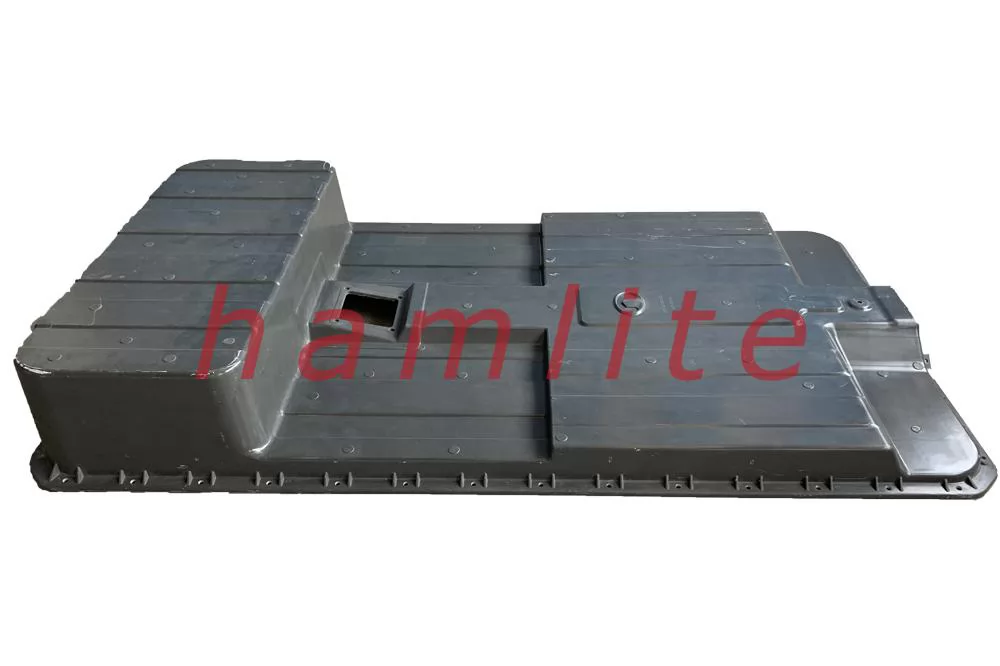

SMC Battery Enclosures

SMC is a very strong, rigid material. SMC enclosures can withstand the heavy batteries at a very low self-weight. This high strength-weight ratio increases the energy-weight ratio and reduces the total weight of battery packs which is very positive for electrical vehicle (EV) industries. Besides, SMC is fire resistant. It reaches V0 or 5VA (UL 94 standards) at a comparatively low cost. This increases safety rate of batteries. SMC is also very design-flexible. It can be molded into almost any shape of enclosures to suite the best usage of space when necessary.

That’s why SMC material is the best material for making battery enclosures.

SMC Battery Enclosures

SMC is a very strong, rigid material. SMC enclosures can withstand the heavy batteries at a very low self-weight. This high strength-weight ratio increases the energy-weight ratio and reduces the total weight of battery packs which is very positive for electrical vehicle (EV) industries. Besides, SMC is fire resistant. It reaches V0 or 5VA (UL 94 standards) at a comparatively low cost. This increases safety rate of batteries. SMC is also very design-flexible. It can be molded into almost any shape of enclosures to suite the best usage of space when necessary.

That’s why SMC material is the best material for making battery enclosures.

Anti-explosive Enclosures

Sheet molding compound (SMC) material, rigid, sustainable, low weight, fire resistant, chemical resistant, and long serving life, is a very suitable material for producing anti-explosive enclosures after adding special mineral agent into SMC material. Explosive working places are always protecting electrical equipments from leaking flashes. Working places are usually in very bad condition. This requires the protecting enclosures being very strong, and most importantly, self anti-explosive.

Anti-explosive Enclosures

Sheet molding compound (SMC) material, rigid, sustainable, low weight, fire resistant, chemical resistant, and long serving life, is a very suitable material for producing anti-explosive enclosures after adding special mineral agent into SMC material. Explosive working places are always protecting electrical equipments from leaking flashes. Working places are usually in very bad condition. This requires the protecting enclosures being very strong, and most importantly, self anti-explosive.

SMC Automotive Body Parts

Sheet & bulk molding compound (SMC BMC) materials have the most important application market that is the automotive market. It doesn’t mean only the vehicles like trucks or cars, but include almost all moving facilities like vans, buses, agriculture vehicles, forklifts, and other moving facilities. SMC BMC materials are widely used for producing body panels like bumpers, air deflectors, front panels, step panels, roof panels, and so on.

SMC Automotive Body Parts

Sheet & bulk molding compound (SMC BMC) materials have the most important application market that is the automotive market. It doesn’t mean only the vehicles like trucks or cars, but include almost all moving facilities like vans, buses, agriculture vehicles, forklifts, and other moving facilities. SMC BMC materials are widely used for producing body panels like bumpers, air deflectors, front panels, step panels, roof panels, and so on.

Train Interior Parts

Similar to the automotive industry, train industry is also a very important market for sheet & bulk molding compound (SMC BMC) materials. SMC BMC materials are usually used for producing train parts like window frames, table/seat structural panels, floor & ceiling panels, washroom panels, driving cabin panels, etc.

Train Interior Parts

Similar to the automotive industry, train industry is also a very important market for sheet & bulk molding compound (SMC BMC) materials. SMC BMC materials are usually used for producing train parts like window frames, table/seat structural panels, floor & ceiling panels, washroom panels, driving cabin panels, etc.

SMC Cable Brackets

Sheet Molding Compound (SMC) molded cable brackets that provided by Huayuan (HAMC) are used in many fields like power stations, subways, bullet train tracks.

SMC Cable Brackets

Sheet Molding Compound (SMC) molded cable brackets that provided by Huayuan (HAMC) are used in many fields like power stations, subways, bullet train tracks.

If you do not find the information you want, please contact us and tell us your needs. Our professional team will give you a detailed mold solution and quotation